Worldwide, there are more than 300 million biological specimens stored at temperatures below -80 °C, but most of them are unusable. According to the U.S. National Institutes of Health, up to 70% of those samples are worthless because the lack of traceability. Without proper environmental storage records, there’s no way to validate the samples have been adequately preserved.

There are two types of cryogenic storage: transactional storage covers specimens that will be used within 3 to 12 months, typically by researchers who utilize that material on multiple occasions. The second is referred to as archival storage, which is for long-term storage.

Developing a storage plan is crucial to ensure the value and viability of samples. Lack of a storage plan can lead to material being compromised, wasting both time and money. When developing a long-term storage plan, there are five key elements that must be addressed.

Storage Objective

First, ask yourself, “why are the samples being stored, and how many samples are being stored?” These questions will instill the value of the research material, so samples will be properly regulated and tracked. When it comes to the number of samples being stored, it’s advised to take that number and triple it, in case of nonfunctioning specimen. Also, properly label testing materials so it is not accidentally thrown away; moldy cheese in the refrigerator can actually be a science experiment!

Biological Viability

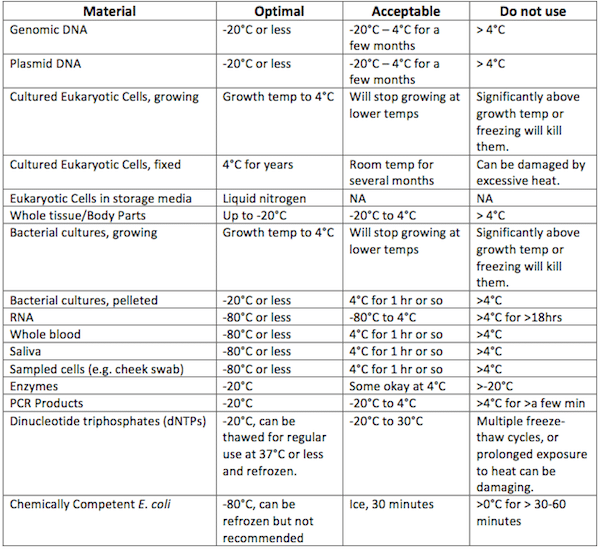

How long will the samples be stored? Depending on the material, you must develop a storage strategy around it. The storage temperature will directly affect how long the material can be kept. Research shows samples prepared properly and stored below -135 °C can be kept infinitely and still serve their purpose.

However, once storage temperatures rise above -135 °C, a strategy must come into play. It must be determined how long the material can be archived before it begins to degrade; that decision will be driven by whether the material is being stored for transactional or archival purposes.

Courtesy: BitesizeBio

Thermal Performance

When developing a storage strategy, temperature controlled units are everything! Creating a cold storage space is based on the quality of the insulation. For example, the difference between a liquid nitrogen-based storage and a mechanically cooled storage box has little to do with the systems’ cooling technologies, but rather the amount of insulation. The thermal performance of a system will increase by improving the insulation.

Environmental Impact

Insulation also plays an important role in the amount of energy being consumed. To put it in perspective, three -80 °C freezers have the same environmental impact as an average family car, and five freezers are equal to the average household’s annual power consumption. In an ultra-high efficiency storage space, if the cooling capacity shut off, the proper temperature will be maintained for about a week. In a mechanically cooled box, that period of time drastically drops to about one hour.

Cost

It is important to consider the overall cost to run the storage space. Besides the cost of electricity to run the cooling systems, one must also consider having to pay for air conditioning to remove the access heat, environmental monitoring, as well as costs for maintenance and repairs.

For example, a university must make large expenditures each year for the collection of genetic material to be processed, distributed and stored.

Summary

Since temperature fluctuations compromise the value of biological samples, data logging systems are often used to ensure proper temperatures are constantly maintained. MadgeTech offers data loggers designed specially to withstand the harsh conditions of cold chain monitoring, including cryopreservation and lyophilization.

To learn more about how data loggers can help validate proper storage conditions, click here.